Share

75.000 €

100% funded by 808 investors

Microalgae Aqualgae II

Viana do Castelo, PT

instalment

monthly

term

3 years

a year

4.5%

rating

B-

Microfactories to produce microalgae.

Description

With Portuguese DNA, Aqualgae is headquartered in Coruña (Spain) and has a manufacturing center in Viana do Castelo (Portugal).

The company is mainly dedicated to the design and manufacture of photobioreactors for the production of microalgae, and the supply of services in essential areas of aquaculture, such as the automation of processes and systems, the installation of equipment and sensors, and the development of platforms monitoring and control.

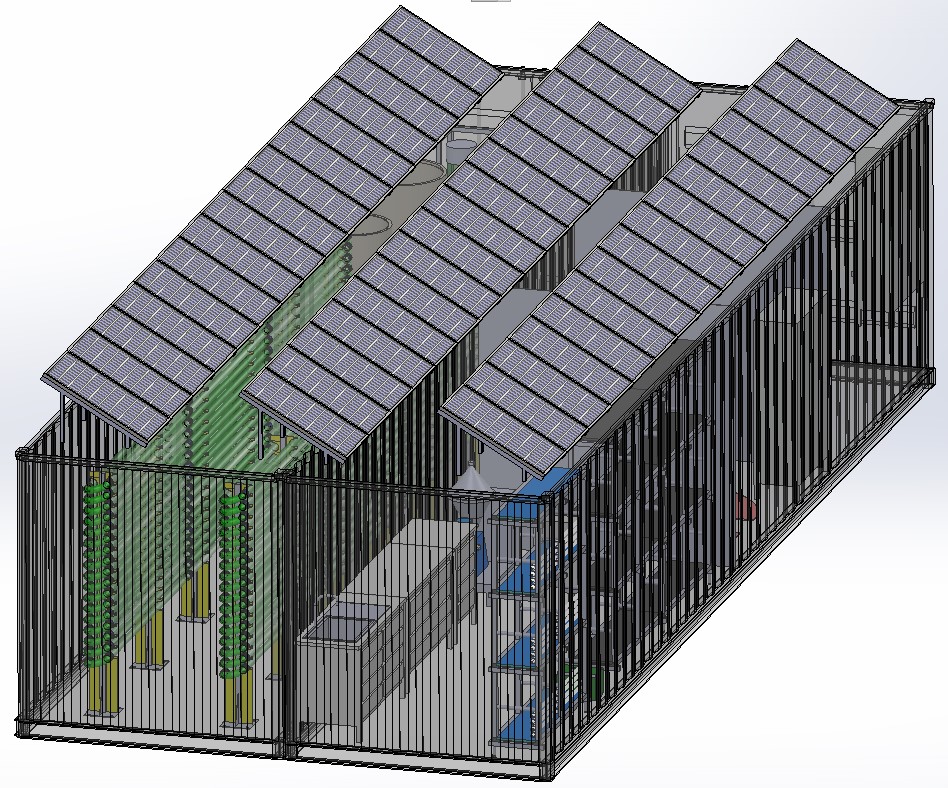

After the first campaign in which the promoter raised 60.000€ to manufacture tubular borosilicate glass photobioreactors, the funds raised through this campaign will be used to develop the prototype of the first modular micro-algae micro-factory in reused containers.

A mini-factory consists of a second-hand reused shipping container with photovoltaic plates on the roof for self-consumption of electricity, two photobioreactors for microalgae production, materials, and equipment needed to produce the microalgae, and remote communication technology to offer customer support.

The widespread uncertainty felt in logistics chains worldwide, and the most recent episodes that compromise geographic mobility, make it mandatory to find solutions that expedite the shipment of equipment and machines, that can be used as plug-and-play solutions, without the need for final installation or on-site demonstrations of operation. These types of equipment should be installed and activated by the end user and operated remotely if necessary. Use, maintenance, and repair should be available through hands-on instructions or remote support.

Microalgae are a sustainable source of proteins and PUFA fat acids, essential for the aquaculture industry, and increasingly used in food and feed, agriculture, cosmetics, and other applications.

This is why Aqualgae intends to develop modular plug-and-play solutions with state-of-the-art technology to be connected with the customer, provide remote assistance and help remotely anywhere in the world. The micro-factory will be partially automated, will have a gateway to access real-time data in the cloud, and will feature a remote assistance and management platform, records, and operational intelligence.

The construction of this prototype will last about 6 months, and operational testing will last at least another 6 months. The first sales are expected after its construction and validation, through dissemination on social networks, trade shows, and on the company's website.

The Impact

Direct:

- Reutilization of shipping containers: shipping containers that are no longer of use in transportation can be reused through small repairs. Aqualgae will reuse one second-hand shipping container for the prototype of the first modular microalgae microfactory.

- Decarbonization of the economy, by avoiding the emission of CO2: the micro-factory will be powered with photovoltaic energy. Solar panels will be installed on an area of approximately 12 x 2,4 m (28,8m2) with a capacity to generate up to 2kWh, enough for the micro-factory's self-consumption, covering the total energy consumed by the LED lighting and temperature control systems integrated in the container.

- Improved productivity through innovation and technological upgrading: compared to traditional methods of producing microalgae in 500L plastic bags or tanks, productivity improvements of at least 500% are expected with this method, with considerable reduction in manual labor demand.

Indirect:

- CO2 absorption: microalgae are responsible for capturing CO2 - for every kg of biomass produced, at least 2 kg of CO2 are absorbed.

- Jobs generation: after the first sales, the promoter can generate 1 or 2 jobs.

Impact Indicators

0 t

CO2 avoided per year

0

MWh clean energy

Contribution to the Sustainable

Development Goals

Sustainable Development Goals

.f6a61f4.png)

.4efc673.png)

.b54aa7b.png)

.628b215.png)

.23930fb.png)

Financial viability

The funds raised through this campaign represent 75% of the overall investment in the project, with the rest being supplemented by the company's own funds. Currently, the company has three clients interested in micro-factories, one in Portugal and two in Spain. In addition to the positive environmental impact through the reuse of used containers, the new equipment has the flexibility of being mobile, is energy efficient, and meets the needs of customers located in several countries in the EU, South America, Africa, and Asia.

A return on investment is expected within 3 years.

Download Key Investment Information Sheet

Guarantees

Pledge of the equipment.

The Promoter

About Aqualgae, Sociedade Limitada - Sucursal em Portugal

Aqualgae is a microalgae engineering and biotechnology company based in Coruña (Spain) with a manufacturing center in Viana do Castelo, in the North of Portugal.

At the beginning, the company was dedicated to the construction of photobioreactors for the optimized production of microalgae, which are the primary food of bivalves such as clams, oysters, scallops, clams, and of the larval stages of sea urchins, limpets and shrimp.

With over 10 years of experience in the aquaculture and microalgae sector, Aqualgae's mission is to innovate and improve the efficiency of the aquaculture industry, particularly the microalgae production systems, in the implementation of automation solutions, increased competitiveness and productivity, greater energy efficiency and consequent improvement in environmental sustainability, and in other industrial sectors that employ microalgae.

Now, in the current context of market instability and lack of raw materials and essential goods, it becomes necessary to produce locally from sea and land. The company's new containerized microalgae production systems (micro-factories), are produced by Aqualgae, and in other industrial sectors that employ microalgae. to obtain biofertilizers for agriculture, or to regenerate poorly productive soils. In turn, in a clear example of circular economy, wastewater from hydroponic agriculture or CO2 emitted in wine fermentation processes are the source of nutrients for microalgae.

The manufacturing and assembly center of the modular systems will be in Viana do Castelo, Portugal.

Aqualgae is composed of a multidisciplinary team of highly qualified professionals in areas ranging from mechatronic engineering to industrial electrical installations, and including market specialists. The company also has a network of local suppliers essential for the development of the project, and proximity to several seaports for export of modular systems: Leixões, Viana do Castelo, Vigo, Marin, Corunha (all in Portugal and Spain).

The team

Business Model

The promoter's main activities are:

- Development and marketing of integral modular solutions for microalgae production and its export.

- Manufacture of machinery for specific use in aquaculture, microalgae biotechnology, hydroponics and biology, agriculture, and related areas.

- Engineering activities, specialization projects, and implementation of technology related to automation, IOT solutions, remote assistance, and development of monitoring and control platforms.

- Development of turnkey projects for aquaculture, microalgae biotechnology, hydroponics and biology, agriculture, and related areas, from design to construction and implementation.

Customers will have the possibility of purchasing the equipment or opting for renting.

Active since

2015

Fiscal country

PT

Operating In

Europe

Industry

Aquaculture

Number of Goparity Loans

2

Women Shareholders

No

Website

https://aqualgae.com/Updates

2022-09-29

First payment

First instalment was paid to all the investors

2022-08-24

100% funded

779 investors successfully raised 75.000€

2022-08-11

Open for investment

This campaign will help avoid the emission of 0 tons of CO2 per year

Sign up to our newsletter and stay up-to-date on our investment opportunities